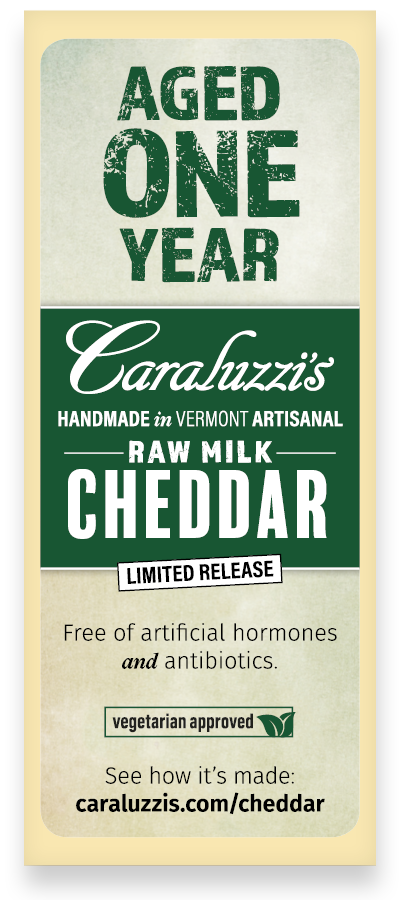

Caraluzzi's Raw Milk Cheddar

AGED ONE YEAR

With some help from our friends from Grafton Village Cheese in Brattleboro Vermont, we are pleased to introduce our very own batch of artisinal raw milk cheddar cheese.

Free of artificial hormones and antibiotics, Caraluzzi's One Year Aged Cheddar is all natural and handmade using traditional methods. Now this is some serious stuff and quite the undertaking, requiring skill and strength, as we learned when we visited Grafton Village last April to partake in the making of our One Year Aged Cheddar. Check out our cheese making experience below!

Caraluzzi's Raw Milk Cheddar is aged for one full year resulting in a velvety, rich and creamy cheddar. It is a mild and pleasant table cheese that pairs well with sliced fresh apples and grapes and is also perfect for melting.

PAIRING SUGGESTIONS:

Wine: Medium-bodied wines such as Riesling, Beaujolais

Beer: Pilsners

CHEESE MAKING 101:

It's all about the milk

Raw milk is delivered fresh from local Vermont Farms to Grafton Village Cheese daily. The milk comes primarily from Jersey cows, a rich milk known for its high protein and high butterfat components. It takes 10 pounds of milk to make one pound of cheddar.

A sample is taken from each milk load and tested for antibiotics prior to being pumped into large storage tanks. All milk used for Grafton cheddar is free of rBST hormones and is all natural.

Cheese making starts when the milk undergoes a heat treatment to prepare for cheddaring. From there, it is moved into the vat where culture is added to it. Upon filling the vat, a vegetarian-approved rennet (a coagulant) is added to the milk. From start to finish, the entire process of making cheddar the Grafton Cheese way takes about five to six hours.

Curds & Whey

After approximately 30 minutes, the consistency of the milk is similar to custard. Curd is then cut with wire knives. The knives are frames with stainless steel wires, one having horizontal wires, the other vertical wires. They are pulled up and down, and side to side of the vat, which separates the curd from the whey.

The curd is slowly agitated by large paddles and cooks for approximately one hour. At the end of the cooking period, whey is drained and pumped into a tank truck. The whey is distributed to local farms where it is used for animal feed and also for land fertilizer. Meanwhile, the cheese maker “banks” the curd to the sides of the vat, making a trench down the middle.

Cheddar is a Verb

After the vat is drained, cheese curd is cut into slabs. The slabs are turned over three-to-four times in a period of two-to-three hours. This is the cheddaring process. While slabs are being turned, samples of whey are taken. The test checks the acidity level of the whey that is still draining from the cheese slabs. When the acidity has reached the correct reading, the slabs are stacked on the side of the vat.

Slabs are put through a milling machine, which dices them into pieces. During this operation, smaller paddles are used to keep the curd from sticking together. After the cheese slabs have been through the milling process, salt is added.

Cheese curd is shoveled into hoops that have been prepared with a disposable nylon liner. These hoops are weighed, covers put on and are placed on a press where they remain overnight.

The next morning, cheese is removed from the hoops and wrapped and sealed into cardboard cartons. They are moved to an aging cooler where the boxes of cheese age.

Courtesy of Grafton Village Cheese, Brattelboro, Vermont